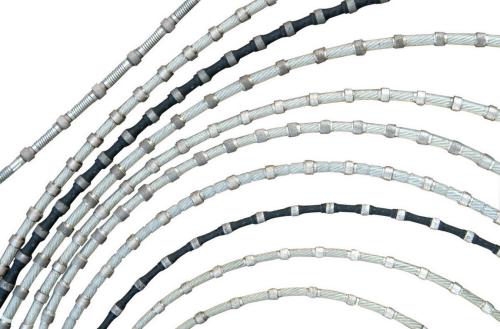

With the advantages of strong spatial geomorphic adaptability, small slotting, fast cutting speed and large waste material size, the mining of stone with bead rope saw can completely avoid the shortcomings of waste, noise, pollution and energy consumption of traditional blasting and flammable mining methods, so as to realize green mining with high efficiency and energy saving. A brief introduction to the application of bead string saw technology in stone mining

(1) marble mining

Bead string saw is the main mining equipment for marble soft mines. In some marble mines with advanced mining technology, the combination of string bead wire saw and chain splitting saw (or chain splitting diamond band saw) is adopted. Chain splitting equipment is mainly used for cutting string saw inconvenient cutting or cutting efficiency very low separation surface, such as the vertical back and horizontal bottom of the separation block and the ore body, in order to improve the mining efficiency, it is the optimal combination scheme for mining separation of marble at present.

(2) granite mining

In view of the best performance and comprehensive cost of mining that the string saw can achieve at present, in mining granite mines, the string saw is used only in one or two vertical sides of the granite separation block and the ore body, while the vertical surface and the horizontal bottom of the granite separation block are connected to the ore body. At present, it is still a row of Kong Zuo. The separation of rock and controlled blasting is carried out.

(3) stone waste plastic

The shaping of stone waste is usually done in mines or processing plants. The use of bead wire saw can be used to plastic large waste material, but from the point of view of the performance and processing cost of the string saw, it is also mainly used for the plastic of the marble mine. For granite blocks, it is usually seldom used for shaping with bead wire saw.

(4) plate cutting

Sheet cutting is the largest process in the stone processing industry. Usually diamond circular saw blades are used for cutting, but the size of the plates is relatively small. Single string wire saw can be cut with large plate and super large plate, and the thickness is not limited, but compared with a frame saw with hundreds of saw bars, the total cutting efficiency is low and the processing cost is high. So the single rope saw is most commonly used in cutting thick plates or large plates with small batches and different thickness. In recent years, multi rope parallel string cutting technology (also called combined Rope saw cutting technology) has been developed. On the same saw, the marble or granite large plate can be easily cut by changing the string of different uses and changing the speed of the string saw line. By adjusting the spacing of the string saw, the thickness of the finished sheet can be changed flexibly. The frame saw has incomparable advantages, so multi-wire parallel bead wire saw cutting technology is a very promising large-scale plate cutting technology.

(5) machining of special-shaped stone products

Bead wire saw machining special-shaped stone is one of the most technical numerical control stone processing technology. Although it has only 15 years of development history, it has become the main equipment for processing high value-added special-shaped stone products. In addition to the common Beaded wire saw special-shaped stone sawing equipment, there are also some small table beaded saw machine, specially used for processing patchwork, curve edge and other special-shaped stone products.

Kanghua fifth generation Power-saving Master series mine wire saw machine

Hard Rock Cutting CNC Automatic Diamond Wire Saw Machine 55kw

Shock! The first Chinese 3D printing wire saw machine was born in Kanghua

Kanghua Wire Saw Machine in Moscow Stone Fair

Hot Sale Wire Saw Stone Quarry Cutting Machine

High Quality Wire Saw Cutting Machine for Quarrying

Diamond Wire Saw Mining Stone Cutting Machine

Granite Diamond Wire Saw Machine for Quarry Stone

Diamond Wire Cutting Rope Saw Machine

Granite and Marble Block Wire Saw Cutter Machine

Hard Rock Cutting CNC Automatic Diamond Wire Saw Machine 55kw

Shock! The first Chinese 3D printing wire saw machine was born in Kanghua

Kanghua Wire Saw Machine in Moscow Stone Fair

Hot Sale Wire Saw Stone Quarry Cutting Machine

High Quality Wire Saw Cutting Machine for Quarrying

Diamond Wire Saw Mining Stone Cutting Machine

Granite Diamond Wire Saw Machine for Quarry Stone

Diamond Wire Cutting Rope Saw Machine

Granite and Marble Block Wire Saw Cutter Machine