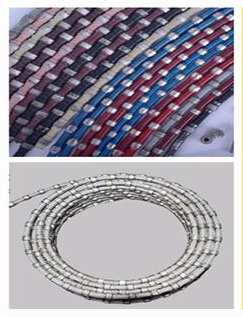

In the 1990s, in order to solve the problem of processing large size silicon wafers, wire saw technology was used to cut silicon rods into pieces. The early wire saw processing technology is using bare metal wire and free abrasive. In the process of processing, the grinding material is added between the third to the metal line and the machining parts. This technology has been successfully applied to the processing of silicon and silicon carbide. In order to further shorten the processing time, and to process other hard and difficult ceramics, the diamond abrasives are fixed to the metal line in a certain way, thus producing a fixed diamond wire saw.

The electroplated diamond wire saw can be made into different diameters and lengths according to the needs; the wire saw can be installed on different equipment to form different processing methods, such as reciprocating cycle (saw frame), high speed band saw, wire cutting and so on. For the machining of hard and brittle materials, wire saw can not only cut thin sheets, but also process curved surfaces, and can be used for the study and repair of small holes. Its application prospect is broad.

Different from previous mortar cutting technology, diamond wire saw cutting adopts multi wire cutting technology. This technology has strong cutting ability and high efficiency; the line size of diamond wire saw is very strict, cutting loss is very small and the precision of cutting out the product is very high. Because of no use of mortar, the working environment is clean, it is a kind of energy-saving and environmental protection product.

Kanghua fifth generation Power-saving Master series mine wire saw machine

Hard Rock Cutting CNC Automatic Diamond Wire Saw Machine 55kw

Shock! The first Chinese 3D printing wire saw machine was born in Kanghua

Kanghua Wire Saw Machine in Moscow Stone Fair

Hot Sale Wire Saw Stone Quarry Cutting Machine

High Quality Wire Saw Cutting Machine for Quarrying

Diamond Wire Saw Mining Stone Cutting Machine

Granite Diamond Wire Saw Machine for Quarry Stone

Diamond Wire Cutting Rope Saw Machine

Granite and Marble Block Wire Saw Cutter Machine

Hard Rock Cutting CNC Automatic Diamond Wire Saw Machine 55kw

Shock! The first Chinese 3D printing wire saw machine was born in Kanghua

Kanghua Wire Saw Machine in Moscow Stone Fair

Hot Sale Wire Saw Stone Quarry Cutting Machine

High Quality Wire Saw Cutting Machine for Quarrying

Diamond Wire Saw Mining Stone Cutting Machine

Granite Diamond Wire Saw Machine for Quarry Stone

Diamond Wire Cutting Rope Saw Machine

Granite and Marble Block Wire Saw Cutter Machine