Have you had such an experience:

- You want to quarry the marble or granite, but do not know what equipment to buy?

- How to design an optimal solution for quarry stone.

- Most quarry equipment is too expensive. Which machine is the best for you.

- Is it easy to operate these machines? Can my workers operate these stone quarry machines very well?

- If the machine is not working, is it easy to repair?

The solution for the question that you have ever faced or you will face will be found here. Do not worry, please read on.

Who are we? What problems can we solve for you?

Our company name is GuiLin KangHua Mechanical and Electrical Technology Co.,Ltd(shorten for Kanghua), We are the manufacturer and supplier of diamond wire saw machine. After watching this video, they all choose Kanghua machine.

What are the advantages of our equipment compared to others?

Kanghua spent five years for researching and developing and produce the fourth generation flagship product diamond wire saw machine. It has the following performance characteristics:

- High production efficiency:Make your output higher and more profitable.

- Stone is no internal injuries:The quality of the quarry stone is higher

- Large size blocks can be mined:Let your stone to meet the needs of market diversification

- Low comprehensive quarry costs:The machine is cheap,One person can operate several machines at the same time

- Environmental protection:Neighboring residents will never complain about the pollution of your quarry

- Security:Security is guaranteed and there will be no casualties in the quarry.

Maybe you don’t believe what mentioned above and think I am bragging.It does not matter, I will prove that they are all true.

Here is a comparison table.Our machine has ten major features:

Metal sheet

| Ours | The metal sheet is thicker (thickness of the metal sheet is 12mm, other brands are 6-8mm).The machine is heavier because the machine is made of thicker metal sheet. When machine is working vibration is very small. Therefore the sawing slot is smallest. And It can extend the lifetime of the wire saw. |

| others | Most use thinner metal sheet . Although some machines are very large in size, Due to they are spot welded, the machine shakes during work and will deform after a certain period of time. |

Power unit

| Ours | The rotary speed reducer of double supports which is researched and developed by our company supports the power unit. The spindle diameter is large and up to 225 mm with heavy load capacity. The power head is supported strongly and operates smoothly. The parallel misalignment between the upper and the lower axis of moving case is very small, so the power head will not drop or tremble even though it is used for a long term. |

| others | The outside diameter of the main shaft is only 140mm. It cannot be repaired except for replacement. Seriously affect the quality of quarrying stone. |

The Lifting lug of equipment

| Ours | The Lifting lug of equipment is particularly designed as an integral structure with the machine body to avoid hoisting accident probably reduced from soldering problem. |

| others | The Lifting lug of equipment is welded to the equipment. |

Bearings

| Ours | The guide wheel is mounted with an integral seal bearings (car bearing) specially designed for wire saw machine. The bearing can be used for over two years and doesn’t need to change. If the aluminum guide wheel is broken, the operator can replace it easily because the dismounting of aluminum guide wheel is very convenient. |

| others | General bearing.At most 3 months,you must change it.And it is very difficult for you to replace. |

Feeding system

| Ours | The feeding system of machine is adopted with a special structure that the distance between the output sprocket of the worm speed reducer and the caterpillar track is adjustable according to requirement. So the sprocket and caterpillar can engage in good condition for long terms. The special sprocket is designed and made as big pitch and heightening gear, so the wire saw machine can work smoothly even the caterpillar is not horizontal on the quarry site. The buttons switches use Siemens which are covered with protection cases to prevent from dust and water. |

| others | Chain drive. The machine must work in a very flat place.And the gearing distance can not be adjusted. |

Drive system

| Ours | The lateral moving of power head is hydraulically controlled fully-automatically to improve the reliability and lifetime of machine. The power head which rotates at 360ºand moves in lateral direction is operated by a hand control box. So the machine can cut stone in any angle. |

| others | The lateral moving of power head is screw driven and easy to fail |

Lubrication system

| Ours | The machine is greasing and has an automatic lubrication function. |

| others | Lubrication using oil. The time for the machine to remain lubricated is short. |

Control system

| Ours | The control system is with function of text display and combination between communication transport and dual PLCs and with only 5 electric wires. So the failure rate is low and the electric fault can be directly shown on the screen of the operating floor. It is convenient for maintenance. The operating floor provides with standby function keys that can be used to operate the machine when the button switches are broken. Production will not stop. |

| others | Traditional way |

Frequency converter

| Ours | The frequency converter has been upgraded to permanent magnet synchronous drive. The torque of motor can be enhanced to 150% which is more strong and powerful and it can be increased with the increase of load. So the wire saw is convenient for cutting stone at low speed. |

| others | General frequency converter; Unable to increase torque |

Inching function

| Ours | Our machine provide with a hand control box with an Inching function |

| others | Most of the other brands have no this function. |

LKH75-6 diamond wire saw Machine Introduction:

Cutting Efficiency: Marble Cutting: 12-16m²/hGranite Cutting: 8-12m²/h

Wire Saw Speed: 0-40m/s

Length of Wire Saw: 20-150m

Cutting Angle: 360°

Features of LKH75-6 Diamond wire saw machine

LKH75-6 Diamond Wire Saw Machine can be used to cut all the types of marble, granite and other stones with max cutting speed, smooth performance and longer working life. With its affordable price and easy operation in the quarry, this wire saw machine is widely used in the stone quarrying.Diamond Wire Saw Machine are fully automatic and there is no need to ask the operator to be at the side of the machine constantly. The running speed of the wire saw can be adjusted with a range from 0 to 40m per minute. And the feeding speed can also be controlled accurately and completely with the help of rail motor.

The Diamond Wire Saw Machine can do ground level and vertical level cutting with a max lateral movement of 2200cm without moving the machine. And with the enlarged gear, this diamond wire saw machine can also work even in slope position and avoid the risk of sliding. Auto hydraulic system is used to control the power head and flywheel direction and position.

Advantages of LKH75-6 Diamond Wire Saw Machine:

- Slewing Reducer with Double Support--Slewing Reducer Shaft Never Moves Down;

- Integral Sealed Bearing--More than 2 years Working Life;

- Permanent Magnet Synchronous Machine--More Powerful and High Torque;

- Screen Display Control System--Lower Failure Rate and Easier Operation;

- Dual Operation System--Guarantee No Breakdown and Continuous Production;

- Integral Lifting Lug--Safe Hoisting;

- Thicker Steel Plate--Strong and Durable;

- Automatic Cutting--Higher Cutting Efficiency and Effect;

- Inching Function--Convenient to Find the Wire Saw Connector;

- Automatically stop when cutting is almost completed--Manual control will work after automatic cutting stops;

Specification of LKH75-6 Diamond Wire Saw Machine:

LKH75-6 Diamond Wire Saw Machine Customers' Plants:

Diamond Wire Saw Machine Factory:

Who has already purchased this machine?

- 2019 New Year's first foreign trade, wire saw machine exported to Morocco,in Africa 2019-01-14

- Two sets wire saw machine are sent to Guizhou Province 2018-10-30

- Regular customer from Guizhou, buy 2 set machines again 2018-06-04

- 2 set wire saw machine will be sent to Vietnam soon 2018-05-29

- 2 sets LKH55-8 to Hunan 2018-05-10

- 2 Sets wire saw machine to Henan province 2018-05-08

- 2 sets wire saw machine to Yunnan 2018-05-04

- 1 set LKH45-8 to Hubei province 2018-05-02

- To Guangdong LKH45-8 2018-04-30

- Two sets machines are purchased by agent in Hunan 2018-04-27

- One set LKH45-6 to Shandong 2018-04-27

- One set LKH55-8 machines are purchased by agent in Guangxi 2018-04-25

- LKH55-8 Orders from Shandong are shipped 2018-04-24

Russia, New Zealand, Myanmar, Ke Vietnam, Ira, China, etc. are all using our diamond wire saw machine

In Russia

In GuiZhou, China

In Guangxi, China

In Iraq

In Vietnam

In Myanmar

In New Zealand

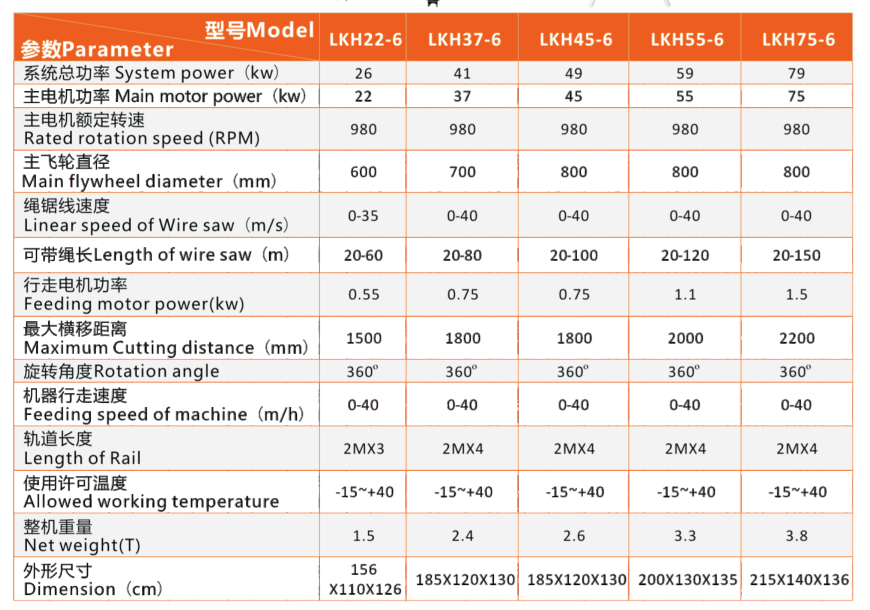

This machine has 5 model

Terms of trade

Normally we conduct the transaction through the trading method of FOB. The buyers will place an order and prepay the seller at alibaba for 30% of the contract value. After we receive the deposit at alibaba, we will deliver the goods to Shenzhen port within 10 to 15days. The buyers will then pay the balance within 3 days after receiving the contract, packing list, proforma invoice, waybill and other relative documents. The seller will pay the freight charge from the factory to Shenzhen port and the fee of customs clearance in Shenzhen customs. And then the goods will be picked up by the buyer’s forwarder.

Of course, we can also do the trade through any other terms of trade, and deliver to any designated port by the buyers. We can deliver our products to any designated place by customers in the world, through your or our forwarder. We can do the trade through alibaba online or offline transaction. But it is the best for going through alibaba payment. It can guarantee the benefits and avoid the risk for both parties.

FAQ

- Q

How many stones can be quarried per hour by your diamond wire saw machine?

A Our machine LKH55-6 can quarry marble 10-15 Square meter per hour.

- Q

Can you help design the stone quarry plan?

A Yes, we are happy to provide this service to our customers.

- Q

What is the company property?

A We are a private enterprise.

- Q

When was your company founded?

A Our company was established in 1991.

- Q

Where is your factory and the delivery port?

A Our factory is located in GuiLin,Guangxi, China, 400kms away from Huangpu port, Guangzhou or 450kms away from Yantian, Shenzhen.

- Q

How often does your company maintain and correct production equipment?

A Government regulators require us to maintain and correct production equipment once a year. Our company's own standard is twice a year. Some equipment and instruments are maintained and calibrated every quarter.

- Q

Do you have an R&D team?

A Yes, we have an R&D team working closely with the manufacture and QA department.

- Q

When will the order be delivered?

A The order will be delivered within 10-15 days after receive of advanced payment.

- Q

Are you able to response customers quickly?

A Yes, our staffs are requested to response customer within 24 hours.

- Q

What management system does your company use?

A We are certified for ISO9001:2008

- Q

Does your company have its own export license?

A Our export license is being applied. At present, we are using the third-party platforms (such as Alibaba) to conduct export transactions.

- Q

How is your product price? Is there any discount?

A The price of the product is the price announced on the website. As for the discount, please pay attention to the promotion activity published on the website.

- Q

How much is your factory area?

A We have two factories and the total area is up to 5,000 square meters.

- Q

What is your main product?

A Our main products are diamond wire saw machine, diamond wire saw and horizontal drills.

- Q

What is the nature of your company?

A Our company is a private company.

Contact us

Email: glkhjd@163.com

Mobile: 086 19142911686

QQ:Mobile: 1787431577

skype: fufufu8768

Addr: No.9,North,Second Ring Rd.guilin,Guangxi,China