This manual of wire saw is limited only to cutting structure of reinforce concrete.

The operation panel should be put on a safety area. The rotation of driving wheel and guide wheels must be at the same plane. The connected rails should be paralleled to the cutting direction.

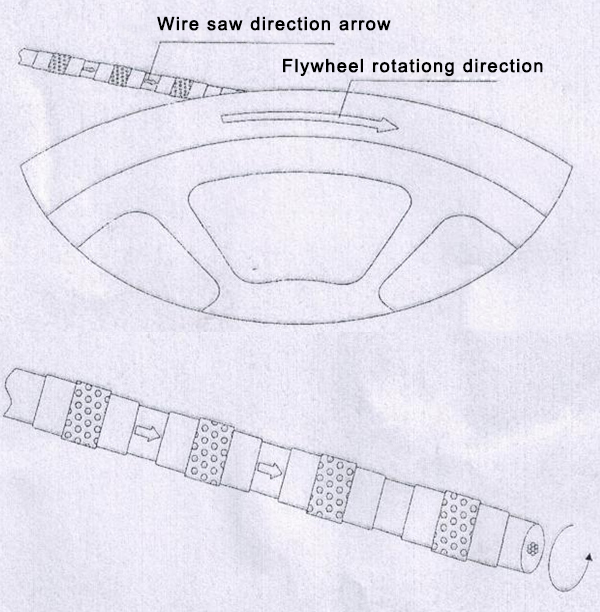

Confirm the Installation of Wire Saw is correct. The method to confirm the correct installation of wire saw: one is to check the arrow direction on the rubber of wire saw. The other is watching the diamond sharpening direction. When the wire saw is cutting, the arrow head is in the front and the arrow tail is in the back. Reverse cutting will affect the lifetime of wire saw seriously.

When connect the wire saw, pay attention to the follow:

Spiral the wire saw: face to the new wire saw, spiral it counterclockwise for 2 rounds per meter. For installation of the used wire saws, the spiral rounds should be corrected relatively, but the spiral rounds cannot be more than 3.5 rounds per meter at most.

After spiral, cut the rubber layer off the wire, the cutting length is a half of the connector. Put the bare steel wire into the connector and press it with a hydraulic clamp. When hearing a sound “ka”, that mean the press is finished. The pressing needs to be repeated at least three times at one point. Then turn it to 90 degree and re-press it at least for the same three times. Connect the other end with the same method. At last, press the middle of the connector for the same three times to finish the whole connection.

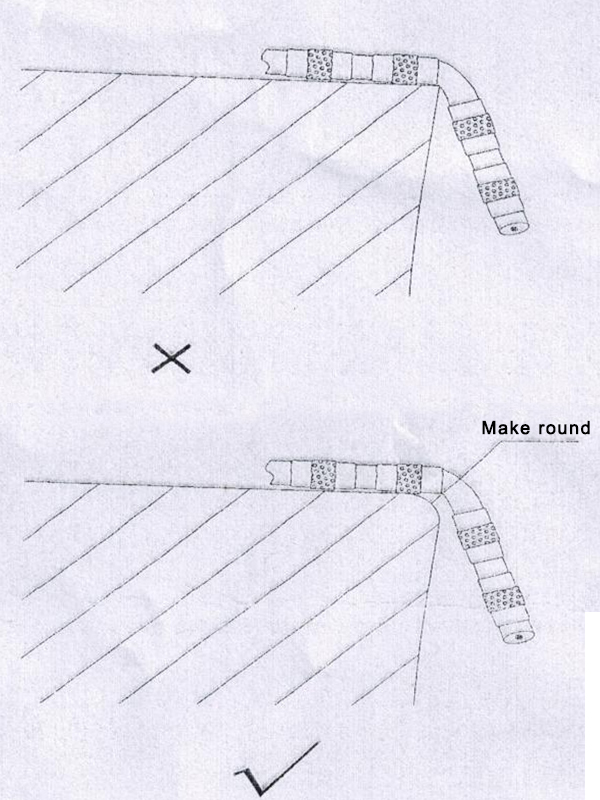

Before start cutting, the corner angles should be made smooth. Then, two people pull the wire saw along the cutting direction, to confirm it can be pulled smoothly.

During working process, the tension of wire saw cannot be too large.

Cooling water: Two water pipes are needed to be put at the inlet and outlet of wire sawing. The flow of water supply is required to be controlled strictly. Flow of too large or too small are not good for wire sawing. And it is suitable when the discharge at the outlet is in a slurry state.

Keeps constant rotation speed of wire sawing. The machine should be stopped for check if the wire saw trembles seriously when cutting. The tremble of wire sawing reduces from unsuitable tension, or the rotation track of the guide wheels is different from the flywheel.

Check the wire saw often to see if the beads are grinded even. If the wire saw is grinded uneven, spiral the wire saw as requirement for some rounds, or adjust the cutting speed to solve this problem.

Safety attention:

All staffs must wear safety helmets before enter working area.

Check the wire saw and the joint to see if there is a crack on it. If yes, cut it away and reconnect it.

Before cutting, put up a safety shield around the rotating direction of wire saw. Confirm all people stay at a safety area during the whole cutting process. Stay near to the rotating wire saw is forbidden, to avoid causing casualty in case of an abrupt breakage of wire saw.

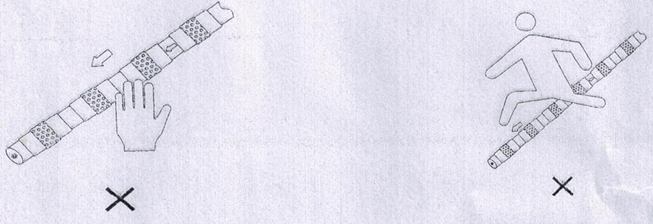

During cutting process of the wire saw, people are strictly forbidden to cross over the running wire rope saw or touch it in hand.

The operation panel should be put up on an open and flat ground at the lateral face of the rotating wire saw, and far away from the machine. Be far away from the cutting quarry stone. Pay attention to mountain slid. Watch out for the cliffs behind and prevent slip and fall.

Stop the machine and check the cutting and using circumstance of wire saw.

All staffs cannot cross over the working area. If necessary, inform the operators and stop the machine.

During cutting construction, pay attention to safety use of electricity and prevent from current leakage, watch out for slide of mountain block. Emergency evacuation to a safe area or designated shelter if a mudslide or landslide occurs.

If multi-machine works at the same time, the distance between the machines should be coordinated well, to avoid the possibility of mutual casualty.

If night construction is required, good lighting conditions must be provided, and a group of two people should take care of each other.

When cutting large plane, use larger diameter of wire saw. When cutting smaller plane and the cutting is nearly finished, change to small diameter of wire saw, to improve efficiency of cutting.